24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

Understanding the Mechanisms Behind Electric Air Compressors: A Deep Dive into Their Functionality

The electric air compressor has emerged as a pivotal tool across various industries, thanks to its efficiency and versatility. According to a report by MarketsandMarkets, the global air compressor market is projected to reach USD 41.4 billion by 2025, with electric air compressors accounting for a significant share of this growth due to their environmentally friendly operation and lower energy costs. Understanding the mechanisms behind these devices is essential for optimizing their use in applications ranging from manufacturing to automotive servicing. In this blog, we will explore the underlying technologies and functionalities of electric air compressors, shedding light on how they operate, the various types available in the market, and their benefits over traditional models. Join us as we delve into the intricacies of electric air compressors and uncover the reasons behind their rising popularity in today's fast-paced industrial landscape.

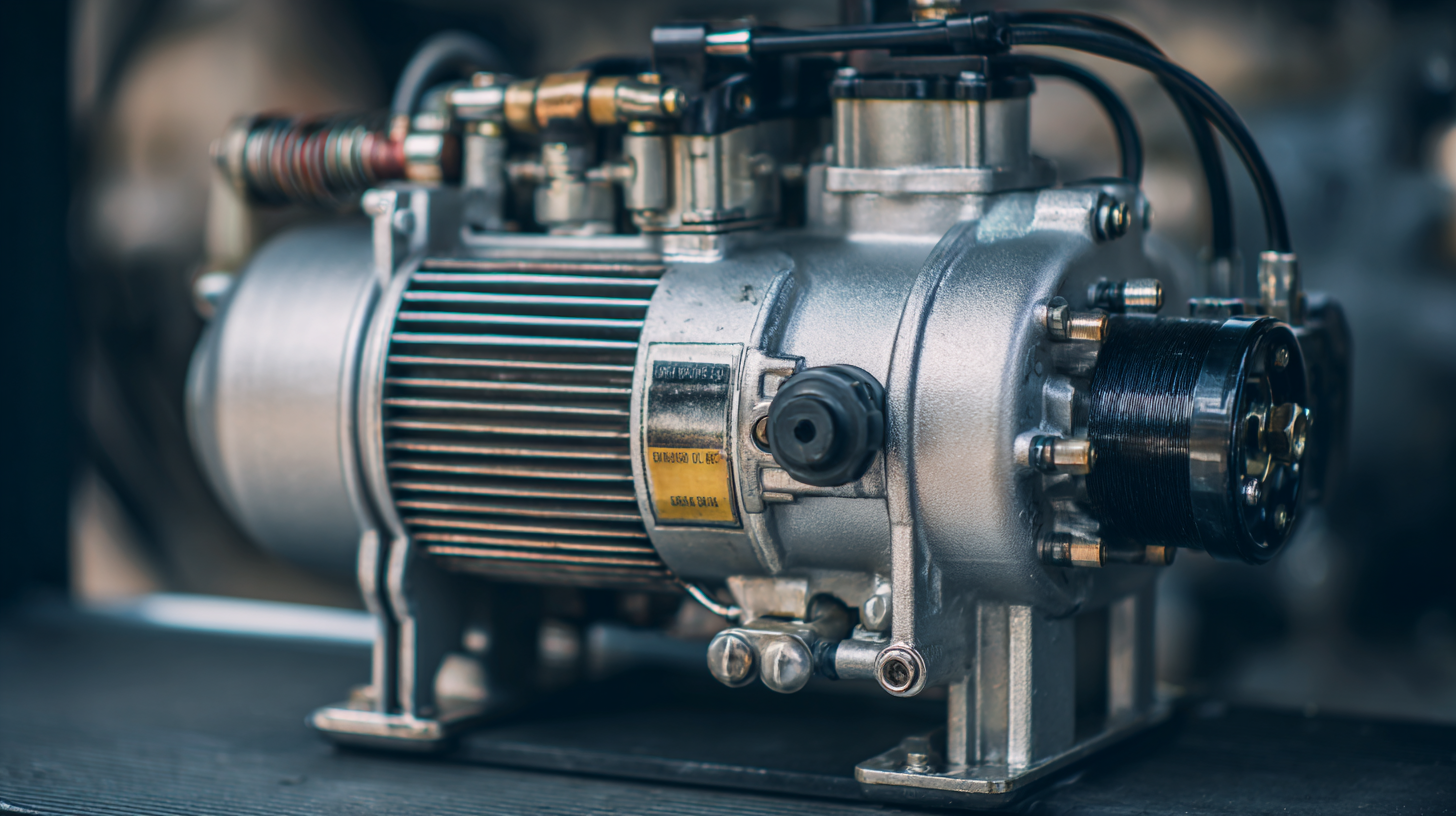

Key Components of Electric Air Compressors and Their Roles

Electric air compressors play a vital role in various industries, providing essential power for tools and equipment. At the heart of their functionality are several key components: the motor, pump, and control system. The motor serves as the driving force, converting electrical energy into mechanical energy. According to a report by Market Research Future, the global electric air compressor market is anticipated to grow at a CAGR of 4.3% from 2022 to 2028, underscoring the increasing reliance on motor-driven technology in industrial applications.

The pump, often referred to as the heart of the compressor, is responsible for compressing the air. It utilizes either a reciprocating or rotary design to achieve the desired pressure. Recent advancements in materials and design have improved efficiency, leading to a 15-20% reduction in energy consumption in modern electric air compressors, as highlighted in a study by the American Society of Mechanical Engineers. Additionally, the control system optimizes performance by regulating air pressure and managing operational cycles, ensuring that compressors operate within their ideal ranges to minimize wear and tear. Together, these components contribute to the compelling performance and reliability expected from electric air compressors in today’s competitive market.

The Science of Compression: How Electric Air Compressors Work

Electric air compressors play an essential role in various industries, utilizing the principles of physics to compress air for a multitude of applications. At the heart of their functionality lies the science of compression, which involves reducing the volume of air while increasing its pressure. This process begins when the compressor draws in ambient air through an inlet valve and uses an electric motor to drive a piston or rotary screw mechanism, effectively compressing the air into a storage tank. The result is a steady supply of high-pressure air, ready to power tools or equipment.

When using electric air compressors, consider these tips for optimal performance. First, ensure that your compressor is well-maintained—regularly check and replace air filters to prevent blockages that can diminish efficiency. Additionally, always monitor the pressure levels; operating at the manufacturer-recommended pressure can prolong the life of your tools and prevent wastage. Lastly, invest in a quality regulator to maintain optimal pressure during operation, which will enhance both the efficiency and longevity of your compressor.

Understanding the intricacies of how electric air compressors function not only reveals their technological brilliance but also highlights the importance of proper usage and maintenance. With the right approach, users can maximize the output and reliability of these powerful machines.

Energy Efficiency in Electric Air Compressors: What You Need to Know

Electric air compressors have gained popularity for their energy efficiency compared to traditional gas-powered models. One major contributor to this efficiency is their ability to convert electrical energy directly into mechanical energy with minimal losses. Unlike their gas counterparts, which rely on combustion processes, electric compressors operate using a more streamlined mechanism that reduces fuel consumption and greenhouse gas emissions. This not only benefits the environment but also results in lower operational costs for users.

Moreover, advancements in technology have led to the development of variable speed drives and smart controllers that optimize performance based on demand. These features allow electric air compressors to adjust their power consumption dynamically, ensuring they only use as much energy as needed for the task at hand. As a result, they are particularly well-suited for applications requiring varying levels of airflow, making them versatile for both industrial and residential use. By understanding these energy-efficient mechanisms, consumers can make informed decisions when selecting air compressors that align with their sustainability goals and budget considerations.

Moreover, advancements in technology have led to the development of variable speed drives and smart controllers that optimize performance based on demand. These features allow electric air compressors to adjust their power consumption dynamically, ensuring they only use as much energy as needed for the task at hand. As a result, they are particularly well-suited for applications requiring varying levels of airflow, making them versatile for both industrial and residential use. By understanding these energy-efficient mechanisms, consumers can make informed decisions when selecting air compressors that align with their sustainability goals and budget considerations.

Common Applications of Electric Air Compressors Across Industries

Electric air compressors are versatile tools widely used across various industries, owing to their efficiency and reliability. In manufacturing, they play a crucial role in powering pneumatic machinery, facilitating tasks such as drilling, cutting, and material handling. By providing a consistent and high-pressure air supply, electric air compressors enhance productivity and enable precise control over machinery operations, essential for maintaining high-quality production standards.

Another significant application of electric air compressors is in the automotive industry. They are employed for powering tools such as impact wrenches and spray guns, making them indispensable for assembly lines and body shops. Moreover, their ability to maintain a steady airflow makes them ideal for inflating tires and providing air for cleaning purposes. Beyond manufacturing and automotive, sectors like construction and healthcare also capitalize on electric air compressors. In construction, they are crucial for operating tools ranging from nail guns to jackhammers, while in healthcare, they power equipment such as dental drills and respiratory devices, highlighting their adaptability and integral role in modern industrial operations.

Common Applications of Electric Air Compressors Across Industries

Troubleshooting and Maintenance Tips for Optimal Compressor Performance

Maintaining an electric air compressor is crucial for ensuring its longevity and optimal performance. Regular checks of the air filter can significantly improve efficiency; a clean filter allows for better airflow and minimizes strain on the motor. Additionally, it's vital to inspect the compressor's oil levels and quality if your model uses oil for lubrication. Low or contaminated oil can lead to increased wear and tear, potentially causing breakdowns.

Troubleshooting common issues can also enhance your compressor's reliability. If you notice a drop in pressure, examine the fittings and hoses for leaks, as even minor leaks can severely impact performance. Ensure that the pressure switch is functioning correctly and that there are no blockages in the intake or exhaust areas. Lastly, routine maintenance, such as tightening loose connections and checking electrical components for wear, helps prevent many problems before they escalate, ensuring your electric air compressor runs smoothly for years to come.

Related Posts

-

What is a Small Air Compressor and How Can It Benefit Your Business

-

7 Essential Tips for Choosing the Best Oil Free Air Compressor

-

Unique Examples of Air Dryer Solutions for Compressors

-

7 Essential Features of the Best Portable Air Compressors for Every Home

-

Understanding the Challenges Faced by Global Buyers in Sourcing Desiccant Air Dryers

-

Ultimate Guide to Choosing the Best Scroll Air Compressor for Your Business Needs