24 Hour Service

24 Hour Service- 800.825.3222

- Now Hiring

- Request A Quote

Blog

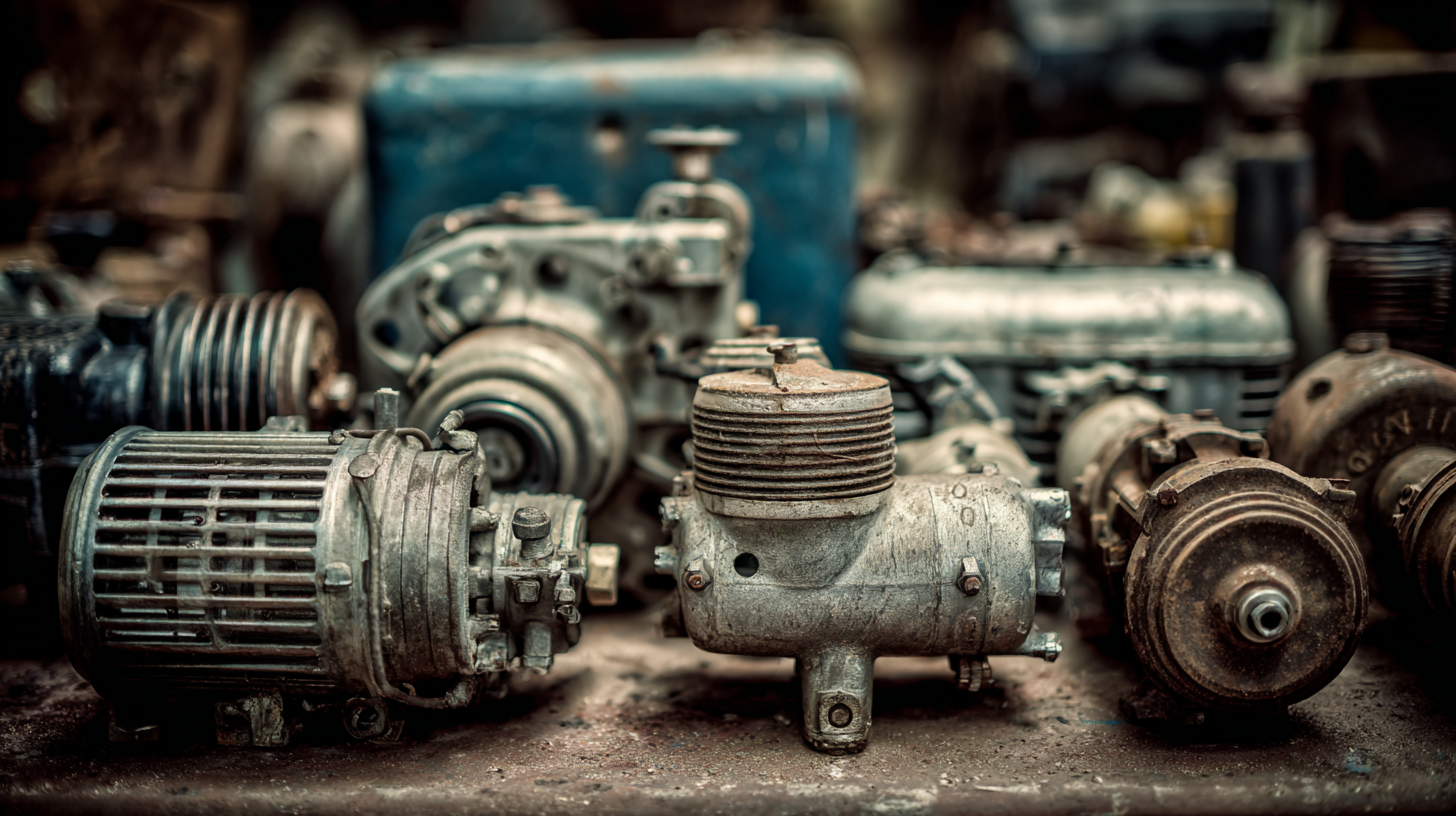

Ultimate Guide to Understanding Air Compressor Parts for Optimal Performance

Understanding the intricacies of air compressor parts is essential for achieving optimal performance in various applications, from manufacturing to automotive repair. According to a report by MarketsandMarkets, the global air compressor market is projected to reach $41.45 billion by 2026, showcasing the critical role these machines play in industry. Organizations that maximize efficiency by properly maintaining and selecting the right air compressor parts can experience significant cost savings and productivity gains. This guide aims to provide a comprehensive overview of the key components of air compressors, ensuring users can make informed decisions and enhance the longevity and effectiveness of their systems. Whether you're a seasoned engineer or a DIY enthusiast, an in-depth understanding of air compressor parts will empower you to tackle any challenges that arise in your operations.

Understanding the Key Components of Air Compressors for Peak Efficiency

When it comes to air compressors, understanding the key components is crucial for ensuring peak efficiency in your operations. The heart of any air compressor is its pump, which compresses the air and delivers it to the storage tank. There are various types of pumps, including reciprocating, rotary screw, and centrifugal, each suited for different applications. Knowing the type of pump your compressor uses will help you maintain it properly and maximize its performance.

Another vital component is the air tank, which serves as a reservoir for the compressed air. The size of the tank can significantly impact the performance of the air compressor, affecting both the flow rate and the cycle time. A larger tank can provide a more stable pressure and reduce wear on the pump, while a smaller tank can lead to frequent cycling and increased energy consumption. Additionally, understanding the role of filters and regulators is essential as they ensure that the air delivered is clean and at the correct pressure for your tools and machinery.

Lastly, proper attention should be given to the cooling system and any safety valves, as they play a critical role in maintaining the overall health of your air compressor. Cooling systems prevent overheating, which can cause damage and reduce efficiency, while safety valves ensure that the unit operates within safe pressure limits. By familiarizing yourself with these key components, you can significantly improve the performance and reliability of your air compressor, ensuring optimal operation for your tasks.

Ultimate Guide to Understanding Air Compressor Parts for Optimal Performance

| Component | Function | Material | Maintenance Tips |

|---|---|---|---|

| Compressor Pump | Compresses the air | Aluminum, Cast Iron | Regular oil checks and change |

| Air Tank | Stores compressed air | Steel | Inspect for rust and leaks |

| Regulator | Controls air pressure | Brass, Aluminum | Ensure proper adjustment |

| Air Filter | Cleans air intake | Paper, Foam | Replace regularly |

| Heat Exchanger | Cools compressed air | Aluminum, Copper | Clean debris periodically |

| Safety Valve | Prevents overpressure | Brass | Test functionality regularly |

The Impact of Air Compressor Size on Performance: What You Need to Know

When considering the performance of an air compressor, one of the most critical factors to keep in mind is its size. The size of the compressor directly influences its efficiency and capability to meet the demands of various applications. A compressor that is too small may struggle to provide adequate airflow, resulting in operational issues and increased wear and tear. Conversely, a compressor that is excessively large could lead to wasted energy and unnecessary costs, as it cycles on and off more frequently than needed.

To determine the optimal size for your air compressor, it's essential to assess the specific requirements of your tasks. This includes understanding the tools and equipment that will be used, along with their airflow needs measured in cubic feet per minute (CFM). By aligning the compressor's output with your demands, you can ensure seamless operation and prolong the lifespan of the equipment. Additionally, considering factors like duty cycle and pressure requirements will further aid in acquiring a compressor that not only fits well within your workspace but also optimizes performance for your projects.

Top 5 Maintenance Tips to Extend Your Air Compressor’s Lifespan

Maintaining your air compressor is essential for ensuring optimal performance and extending its lifespan. Just like air conditioners, air compressors can suffer from unnecessary wear and tear if not properly cared for. Here are some top maintenance tips to keep your air compressor running smoothly.

First, regularly check the oil levels and change the oil as needed. Clean, fresh oil reduces friction and keeps internal components functioning properly. Additionally, pay attention to the air filter; a dirty filter can restrict airflow, leading to overheating and reduced efficiency. Make it a routine to inspect and replace the filter as necessary.

Another crucial tip is to drain the tank regularly. Water accumulation within the tank can cause rust and degradation of the compressor's internal parts. By releasing the moisture, you not only enhance efficiency but also prolong the life of your compressor. Finally, ensure proper placement and ventilation of your air compressor to prevent overheating, especially during high-temperature days. Following these maintenance practices will help you achieve better performance and longevity from your air compressor.

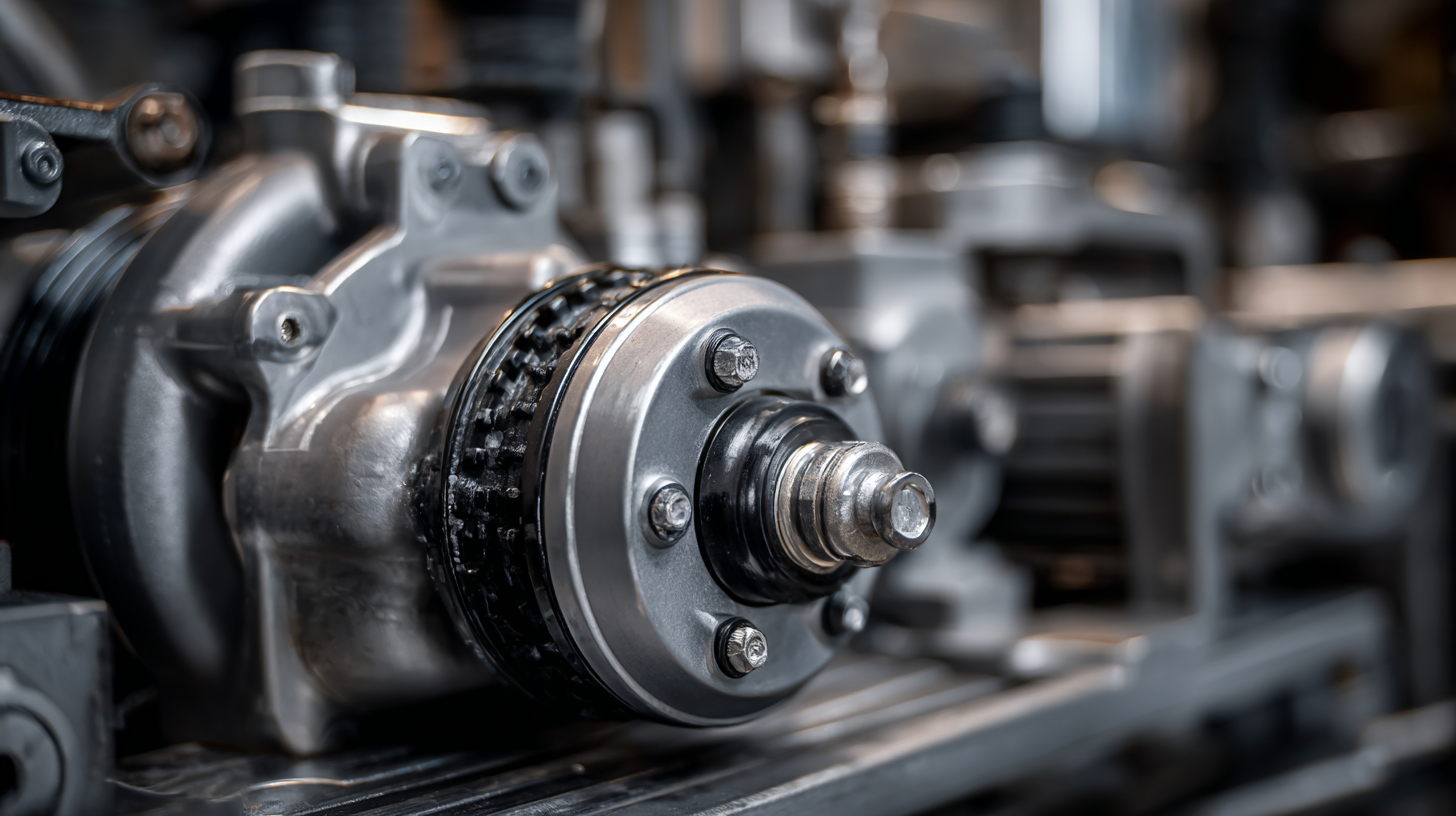

How Proper Lubrication Enhances Air Compressor Functionality and Reliability

Proper lubrication is essential for enhancing the functionality and reliability of air compressors. A well-maintained compressor significantly improves its performance, leading to decreased wear and tear on its internal parts. According to industry studies, air compressors that utilize adequate lubrication can experience up to a 30% longer lifespan compared to their poorly maintained counterparts. This highlights the necessity of integrating quality lubricants into the maintenance routine to ensure optimal performance.

The choice of lubricant plays a crucial role in operational efficiency. For instance, oil-free air compressors have gained popularity due to their reduced maintenance needs and lower operational risks, yet they often require specialized lubricants to perform effectively. Recent reports indicate that using the right grease can minimize friction, optimize power transfer, and improve energy efficiency by up to 15%. This is particularly important in extreme weather conditions, as lubricated parts within compressors are better equipped to handle fluctuating temperatures, thus maintaining readiness and reliability.

Furthermore, automatic lubrication systems have emerged as a reliable solution for continuous maintenance in industrial machines, ensuring that compressors operate smoothly without the risk of human error. Studies suggest that these systems not only enhance the operational efficiency of compressors but also significantly reduce maintenance downtime, enabling businesses to maximize productivity and minimize costs. The integration of these advanced lubrication technologies prepares air compressors for challenging operating conditions while enhancing their overall durability.

Understanding Air Compressor Performance and Lubrication

This chart illustrates the efficiency of oil-lubricated versus oil-free air compressors. Proper lubrication significantly enhances the operational efficiency of compressors, demonstrating why oil-lubricated compressors achieve up to 90% efficiency compared to 70% for their oil-free counterparts.

Decoding the Air Compressor Ratings: PSI, CFM, and Their Importance for Your Needs

Understanding the ratings of air compressors, such as PSI (pounds per square inch) and CFM (cubic feet per minute), is crucial for selecting the right unit for your specific needs. PSI indicates the pressure level the compressor can deliver, which is essential for applications requiring high force, such as powering nail guns or paint sprayers. On the other hand, CFM measures the volume of air delivered; higher CFM ratings are preferable for operating tools that demand consistent airflow, like impact wrenches or air sanders. Matching these specifications to your tools is key to achieving optimal performance in any project.

Additionally, integrating storage receivers into your compressed air system is vital for efficiency. These receivers act as reservoirs that maintain a steady air supply, reducing the load on compressors and minimizing rapid cycling. This is particularly relevant when considering portable air compressors potentially used on job sites or for home projects. Choosing the right model with adequate storage capacity can enhance performance and make tasks smoother and faster, ensuring that you can finish your work effectively without interruptions.

Related Posts

-

Unveiling Creative Applications of Screw Air Compressors in Modern Industries

-

The Definitive Ultimate Guide to Choosing the Right Desiccant Air Dryer for Your Needs

-

Unique Examples of Air Dryer Solutions for Compressors

-

Understanding the Challenges Faced by Global Buyers in Sourcing Desiccant Air Dryers

-

What is a Small Air Compressor and How Can It Benefit Your Business

-

7 Essential Tips for Choosing the Best Oil Free Air Compressor